After 9 years of service without any problem and a production of almost 150’000 kWh, our STP15000TL inverter suddenly decided to stop working.

The displayed showed a cryptic Error 7702. Accessing the device through its Bluetooth interface by using the SunnyExplorer software didn’t bring more information. The error was labelled 77 in the software. Recommendation was to contact the manufacturer of the inverter.

Searching the internet revealed that this error could be related to the AC (grid) relays.

For safety reasons, the inverter was obviously disconnected both on AC and DC sides using the externally available circuit breakers.

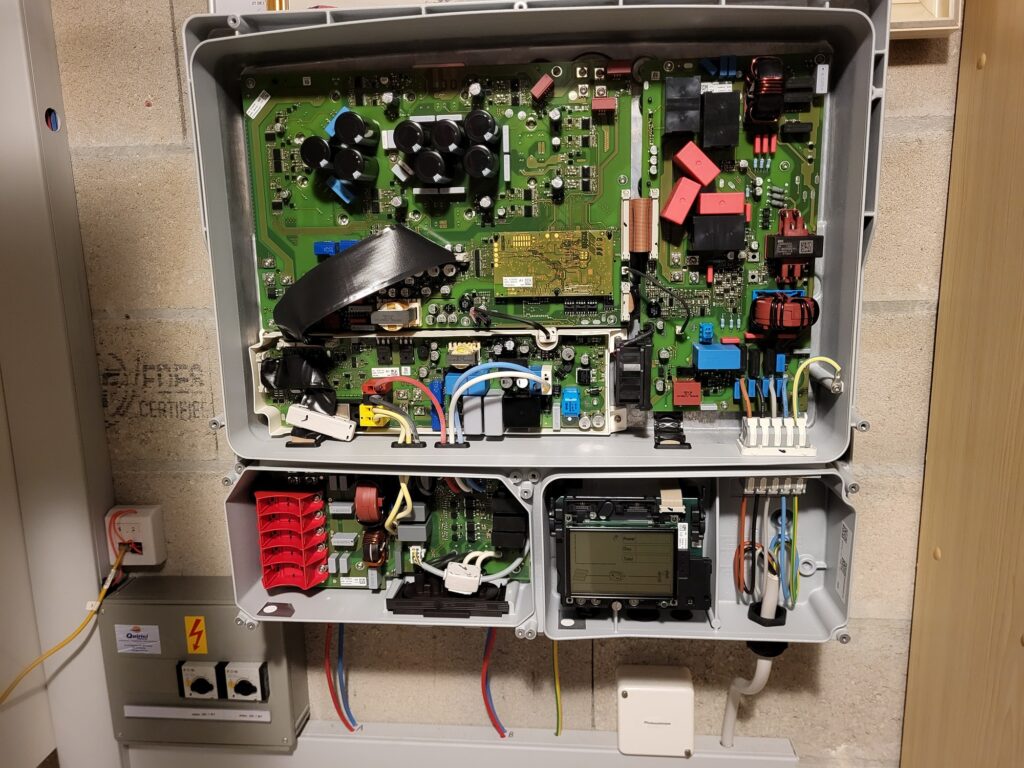

Few screws later the device was revealing its internal life.

The bloc connected to the mains (AC) is easily visible on the top right, above the LCD display.

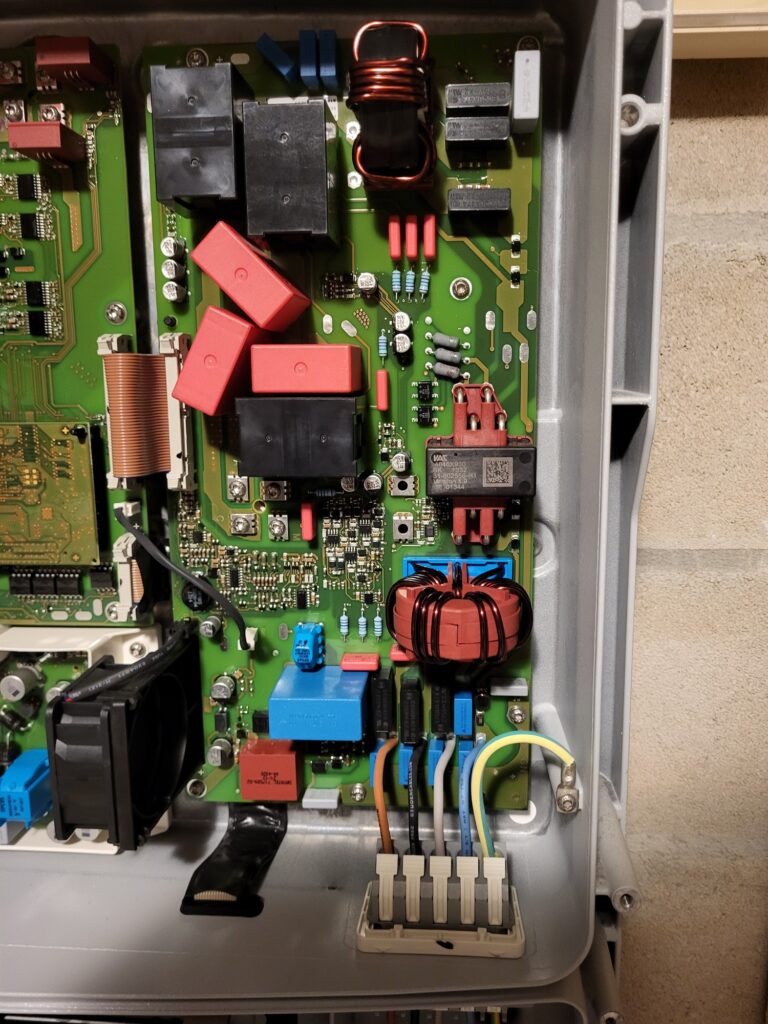

The possibly guilty relays are the 3 black rectangles (one per AC phase). The next step was to remove the PCB from the inverter chassis. This is an easy step, requiring only disconnection of:

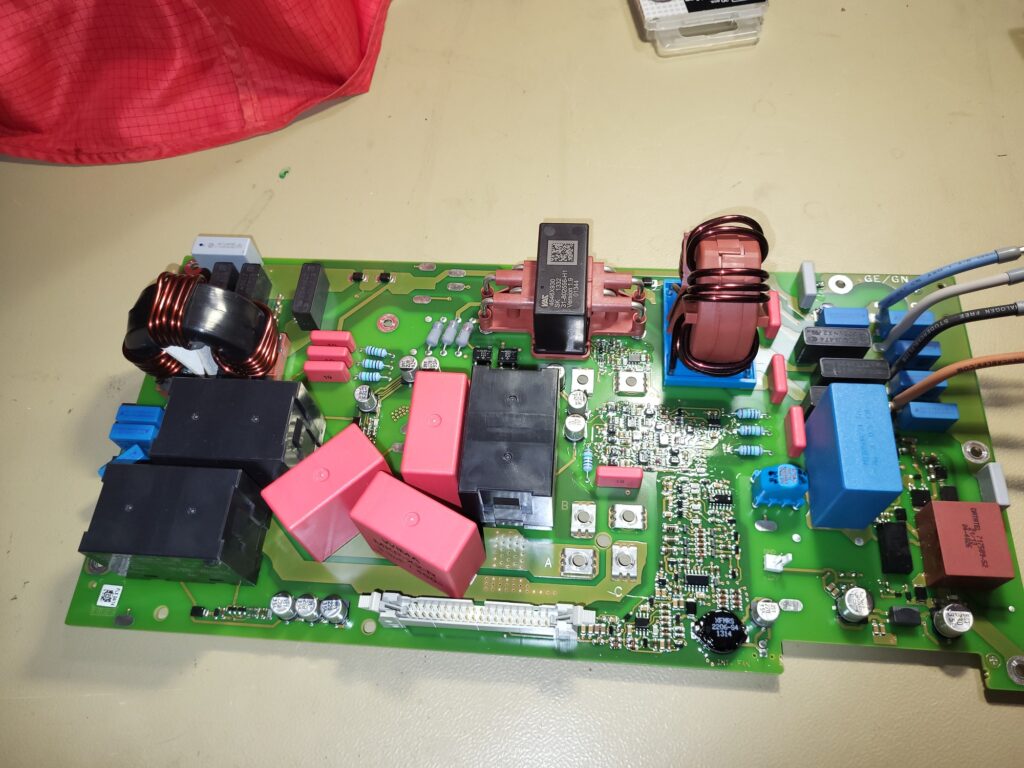

- 3 phases from the mains + neutral. (GND is connected to the chassis and therefore can be left connected)

- 1 ribbon flat cable

- 1 dual-pins cable

- Several screws, some connecting electrically the PCB to the back part of the inverter where the power electronics is located

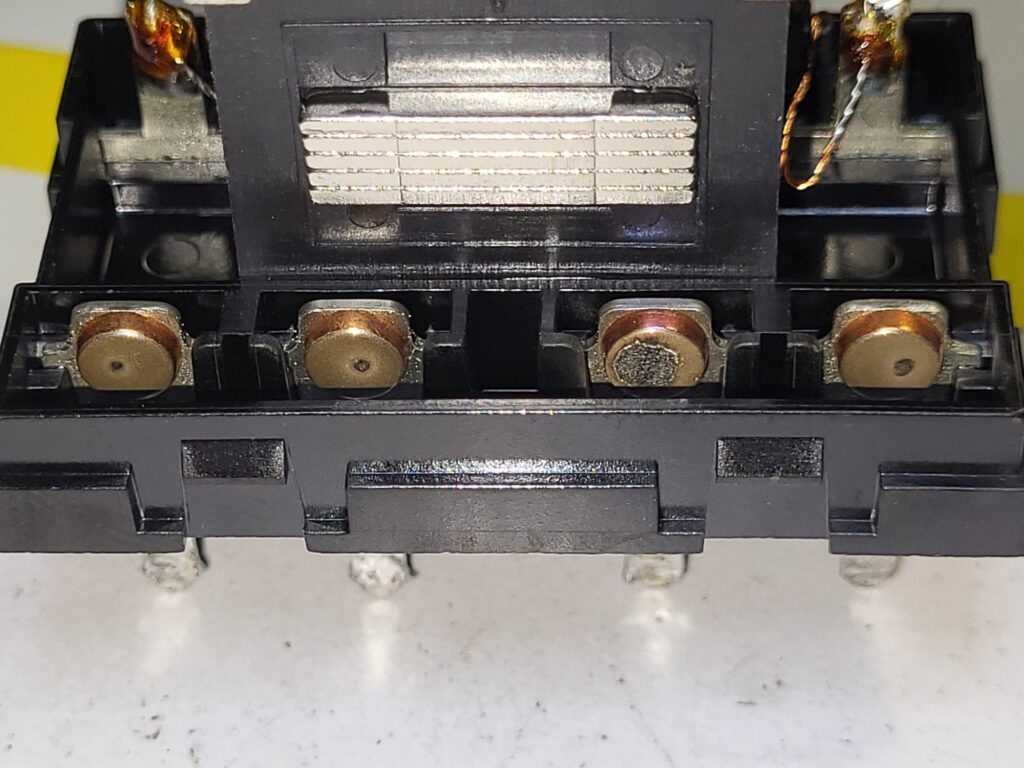

Unsoldering the 3 relays was far from being easy. The PCB is thick, with very large lines, leading to quite some heat dissipation. This structure is needed to carry up to 15 kW AC power!

A 100W soldering iron was used in conjunction with an industrial heat gun to provide enough heat. A de-soldering pump was used to clean-op the solder on the relay pins.

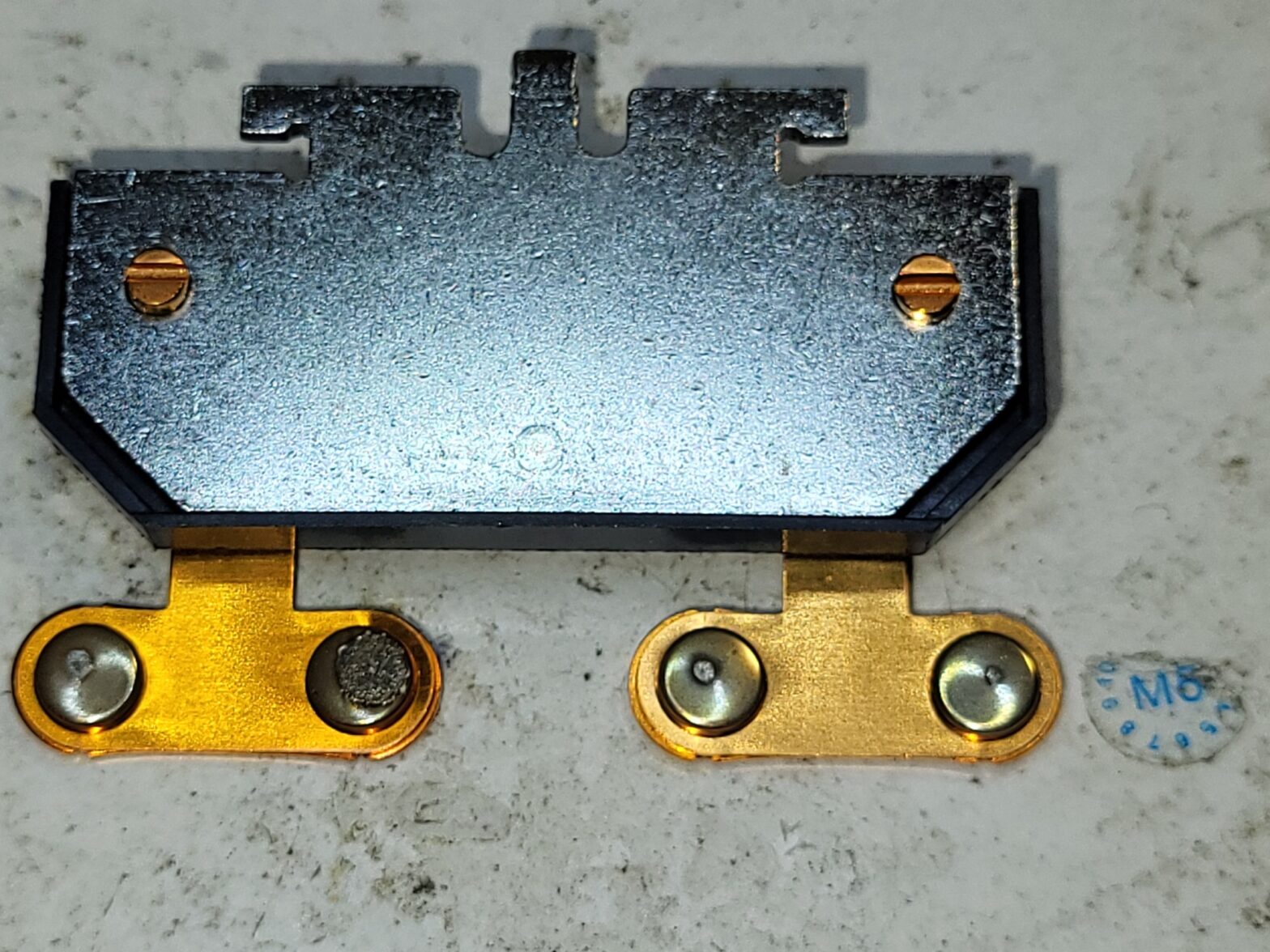

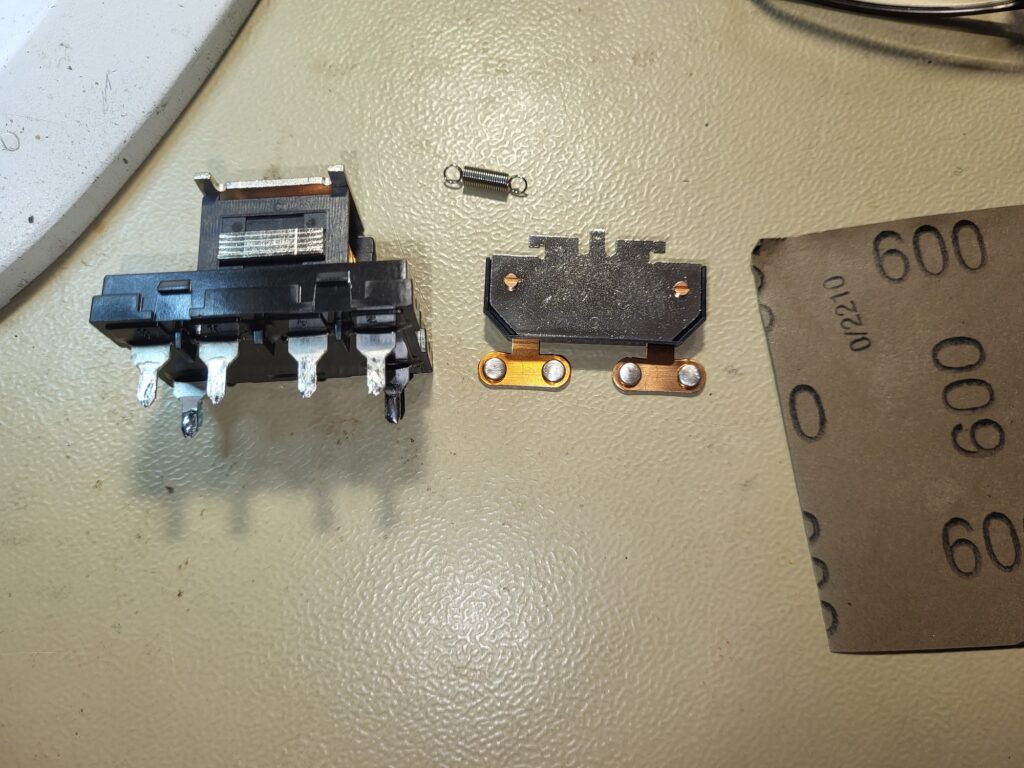

Once de-soldered each relay is easy to open. The relay covers are clipped and can easily be removed. Below is an example of a disassembled relay.

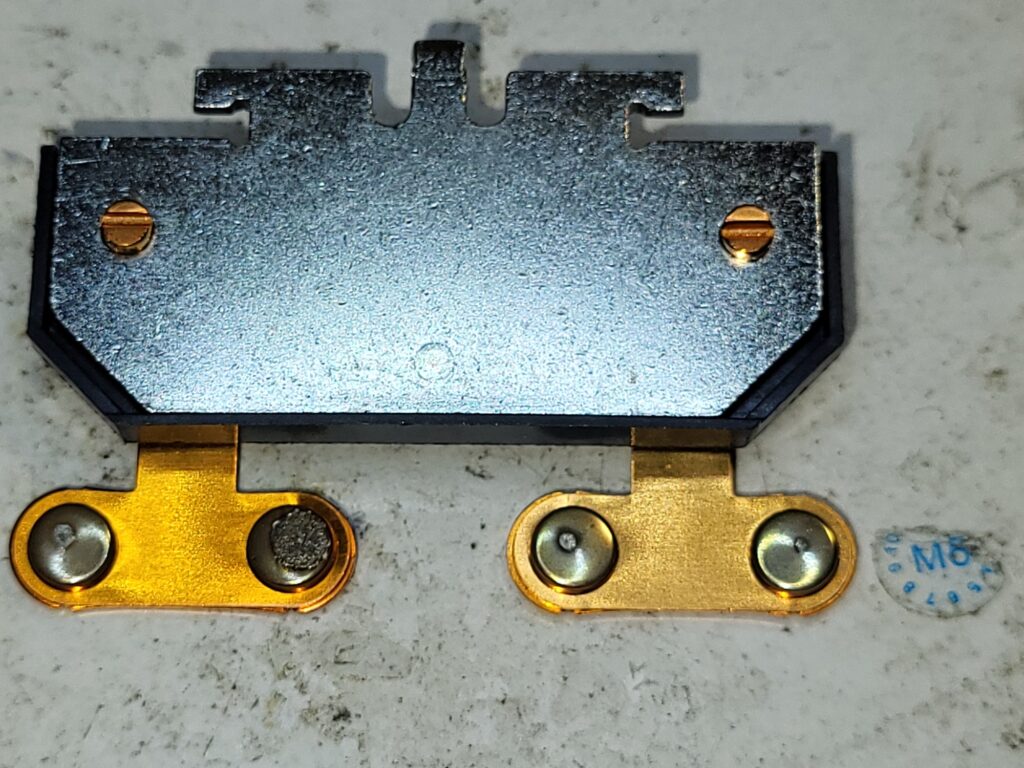

Of the 3 AC relays, one had a very damaged contact, on both the relay blocs and the movable contact bar. For some reason (dust, malfunction,…) the contact started to heat and corrode, leading to increased contact resistance over time. At some point the monitoring system of the inverter tripped into default.

The short term fix was to polish the relay contact with a file and sand paper to remove the ugly looking surface.

This was sufficient for the inverter to restart producing photovoltaic energy at full power. But the contact surface has been damaged, and it is not clear how long such a repair could last.

By chance relays from the exact same type are still available from a local electronic handler. So the next step is to replace the relays by new ones for a long term repair.

Disclaimer: High voltage is dangerous potentially deadly. Operation only to be done by knowledgeable people!